Broken, Rusty, Seized, Bolts, Studs, Etc. How do you deal with them?

Here are some of my weapons of choice, from left, very expensive Lawson solid carbide bits, for the really hardened materials, (will cut glass) inexpensive Vermont American (set 13484 $35) stubby set for soft materials, both left hand cutting.

These Supertanium XL-125 left hand bits from Lawson are good mid priced bits that seems to work very well on all materials, they hold up well under abuse such as overspeed.

Lawson also has these gems, they make sure you are drilling down the center of the broken piece, they come in all sae and metric sizes.

If you are doing this sort of work, you will need broken tap extractors, by Walton tools, you will break a tap once in a while.

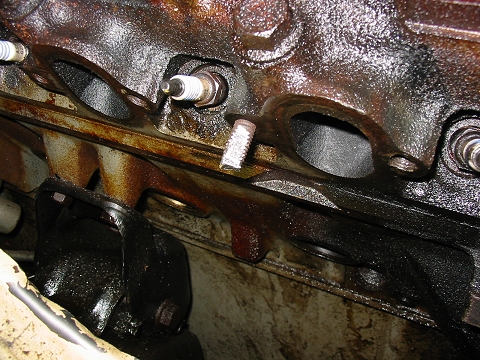

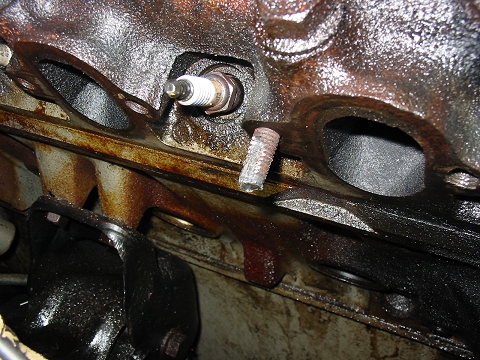

An example of the extreme, 85 Ford Class C Motorhome, E350 Van Chassis, 460 V8, 60k bolts on this rig were so rusted there was not much left of the heads to put a socket on, so they had to be burned off. When faced with this situation, don't use locking pliers on whats left of the bolt, they will just tear up whats left of the bolt and you will have to drill and tap. Grind a flat on both sides of the area left sticking out...

Then you can use a big cresent to get it turning, don't go into it all at once, put a fair amount of pressure on it and hold it there for a while, it may just break lose and save you drilling and tapping. I did every one of them this way on this job. (along with lots of penetrant)

Turned a slight amount, now I just work it back and forth til it frees up entirely. Use the steady pressure method on all exhaust manifold bolts, and you may not break anymore removing them. A lot of shops would refuse this job, it was a favor called in, manifolds were ok, $1000 parts and labor.

Most wheel tubs are easily removed and allow much easier access to exhaust manifolds.

This makes it a lot easier to drill broken bolts or just work on them in general.