A good compression tester is in order, make sure it's an analog gauge, we'll talk about why later, also make sure it has all the adapters to fit your needs, next, a good ignition tester would be nice, there are several

types available, just a basic spark tester, to a full blown digital that can show everything, finally a good leakdown tester, this is a must to look at combustion chamber sealing. Even a test light can locate a miss.

Above, left to right, point type ignition, HEI ignition, distributorless ignition, coil per plug ignition.

So, is it a misfire, or a rough idle? A rough idle I wouldn't consider a misfiring engine, a misfire is a regular loss of power contribution by one cylinder, usually the same cylinder, there can be multiple misfires,

and random misfires. To start with, lets just begin with a single cylinder misfire on a four cylinder engine, lets talk about locating the miss first, then move on to why its misfiring. You really can't imagine how

many things can cause a misfire, it boggles the mind, but first lets concentrate on locating the miss, you would be amazed how many ways it can be determined, lets use a early four cylinder without any control

systems, just a basic carburetor engine, with a distributor ignition system, the most basic way, would be pull a spark plug wire off each spark plug til you find one not lowering engine rpm, while that can be shocking,

an easier way would be short out the plug wire with a test light, or even just a ground wire with some type of probe to shove in the boot end of the wire. This is the way we did it back in ancient times believe it or not.

Once the offending cylinder is found, a compression test is the next thing to consider, followed by a leakdown test, this will eliminate most sealing issues of the engine. You might think you want to look at something

else, but don't sidestep these tests, always do them first, they will save you a lot of wasted time looking beyond them. You will end up pulling the spark plug, so you can see that, and do a quick spark test too.

Whats the most common cause of misfire, and what is required for proper cylinder firing?

Lets start with fuel, air, compression, and ignition. What do you think would be the one thing

most often to cause a misfire, if you asked three different techs, you'd get three different answers.

If you asked me, I would say the most frequent would be ignition problems, here are just a few.

Above, the terminal was corroded with rust, it would not allow the secondary thru the wire

into the spark plug terminal, so the easier path can be to the spark plug shell, there's your misfire.

Typical burnt out plug wires, usually caused by people who don't know how to properly remove a wire

from a plug, pulling on just the wire, not the boot, resulting in breaking the core and it proceeds to burn out.

Definitely the case here, every wire on one bank, burnt out, more wannabe's. Just a few examples of what can cause a misfire,

you couldn't imagine everything at one time in your mind, there are so many, its hard to even think of them all, one at a time.

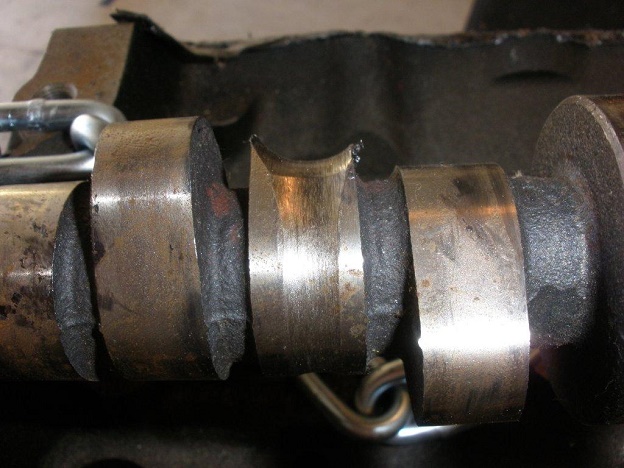

If you have a flat lobe on the cam, it will cause a loss of cylinder filling from no flow through the cylinder on either intake or exhaust valves. Loose valve guides will cause the valve head not to align

with the seat properly losing its seal during combustion, also, guides may run dry from over sealing and stick open also creating loss of seal to the combustion chamber.

The missing rocker causes no flow loss of filling, same as the flat cam lobe, burnt exhaust valve, hole in piston, bad head gasket, all cause combustion chamber loss of seal, intake valve deposits, cause loss of flow or valve held open at the guide.

Lots of things will cause a misfire, finding the cause can be a headache, just don't let it get the best of you, its a lot easier than you think to find the reason why, here are some of the things that will help you to find the problem.

A simple compression test, will probably be the one thing to begin with, all we're doing is testing cranking cylinder pressure to confirm cylinder sealing, and the simple method is with a compression gauge that would thread into the spark plug hole.

When you crank the engine on each cylinder assuming your testing all cylinders (recommended) develop at least four cylinder puffs for each cylinder, another words, stay consistent for each cylinder, and record your reading, you should see a

minimum of 125 psi and a maximum of 190 psi for most engines, more or less indicates a problem, and will put you in misfire territory. If the low reading is from a single cylinder, check it with oil for worn-out piston rings, or it may have a burnt valve.

If you notice 2 adjacent cylinders with low PSI readings, it most likely will have a blown head gasket between the two. Low compression in all cylinders could be caused by incorrect valve timing. These are most mechanical issues that cause a misfire.

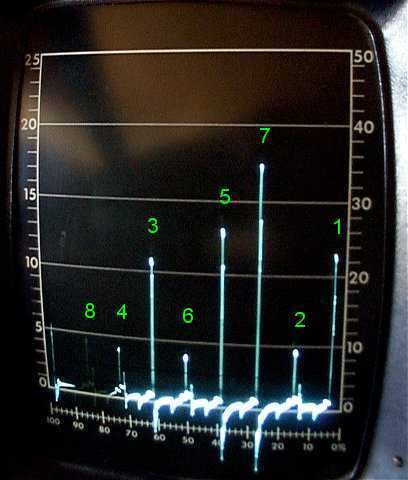

A running (dynamic) compression test measures how efficiently each cylinder is drawing air into the cylinder and retaining it for the correct amount of time then releasing it into the exhaust.

Create a chart similar to this example to record your test readings.| CYL | CRANKING-(STATIC) | IDLE | SNAP |

| 1 | ? | ? | ? |

| 2 | ? | ? | ? |

| 3 | ? | ? | ? |

| 4 | ? | ? | ? |

Begin with cylinder number one and with the engine running, record the idle reading

on the chart, it should be 50-75 (PSI) (about half of cranking compression). Assuming

you already did the static test and recorded the results, you can use the readings to

check the idle and snap readings on the dynamic test, as long as the static test was ok.

Now do a snap throttle and see what the reading is and record it, should be about 80%

of the static reading, do this on all cylinders to see that there are no huge differences.

If you find a low snap reading, a lot lower than 80% of cranking pressure, look for intake air flow problems.

Major carbon deposits on intake valves, worn camshaft lobes, rocker or push rod problems.

If you find a snap reading a lot higher than 80% of cranking pressure, it means the air is not leaving the

cylinder efficiently. Look for problems on the exhaust side, worn cam lobes, bent pushrods, collapsed lifters.

If the snap readings are all high, look for exhaust restrictions, such as a plugged cat or exhaust system.

A low idle and snap reading indicates

that the cylinder is not holding compression, look for

issues,

slightly bent or burned

valves, excessive carbon

buildup on valves or seats,

worn valve guides and springs,

broken or weak piston rings, scored or cracked cylinder walls, leaking head

gasket, cracked head.

Now, perform a cylinder leak down test to narrow down where the leakage is coming from.

In a leak down test the piston is set to tdc on the compression stroke, with the leak down

tester attached to the offending cylinder, we then fill the cylinder with air pressure.

The tester measures the volume of air needed to maintain a set pressure in the cylinder.

The cylinder leak down test reading is expressed in a percentage.

So, the good cylinder leak down readings should be below 10% or less.

The great thing about the cylinder

leak down test is that, it deals with how well the cylinder

is sealing and

nothing else. Another great feature of the cylinder leak

down test is the fact that you can hear where the air is

leaking out of the cylinder. When a cylinder has a high

percentage of leakage, first check the oil filler cap. Do

you

hear a hissing sound? If so, you may have pressure leaking

by the rings. Is there air

escaping out the exhaust?

Is it escaping out the intake system? Then a burned valve

may be the problem. If two adjoining cylinders have

similar low readings and you hear leakage out the

other cylinder then a failed head gasket may be the problem.

- Tailpipe – exhaust valve/seat, cylinder head gasket, cylinder head

- Throttle body, intake, or air cleaner – intake valve/seat, cylinder head gasket, cylinder head

- Radiator – cylinder head gasket, cylinder head

- PCV, Breather, oil fill, dipstick tube – piston rings, cylinder wall, piston, cylinder head gasket, cylinder head