Leak Testing Evap Systems

Dealing with the dreaded P0442 code. Don't let this code intimidate you, it's all in a days work.

The tools you have to test these systems are a major factor in how quick and easy you will

eliminate that "very small leak" you are given the task of finding,

lets start with some basic stuff that will make your life easier.

Get a descent combustible gas detector, these are great for finding fuel and vapor leaks for more than just evap system work,

this one is made by General tool, it will detect as small as 5ppm, just make sure you get a good one with good specs, this will

be one tool you can use to find the leak, it might nail the leak using it first, the trick with these, is keep the shop doors closed,

and try not to disturb the air when you are using it, very similar to checking for Freon leaks, and they are not terribly expensive.

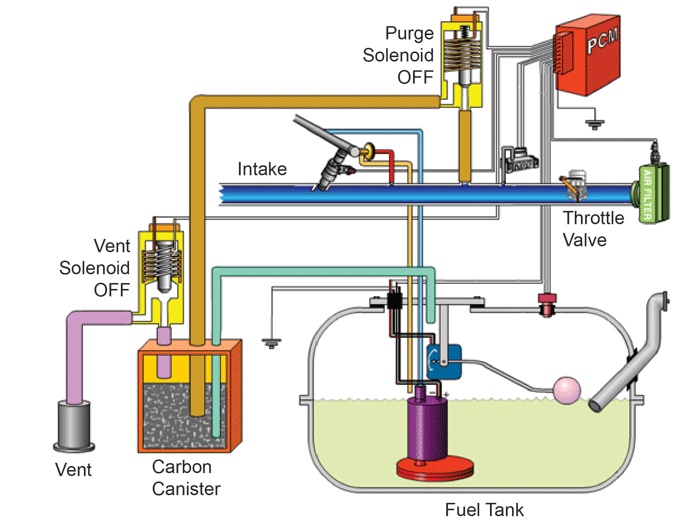

A common pcm controlled evaporative system, this uses a pressure sensor at the top of the

tank to monitor tank pressure to check for leaks, maybe we can use it for leak testing?

With this procedure, we are going to begin looking for the leak at the tank only first, then work our way out from there.

This will not require the use of a smoke machine, I will get into that later in this article, this is for those who don't have one.

You will need to pressurize the tank and have it hold the pressure, Mityvac makes a combo vac/pressure pump pictured above,

that should be capable of the job, we don't need to put too much pressure on the tank, holding it would be possible with one

way valves (shown) if necessary, possibly the pump itself might be capable of holding the pressure, those spark plug boots make good

connectors to use on the canister nipples and so forth, there also are rubber caps in various sizes to plug them off.

Most everyone has a scan tool of some sort, with one you could monitor the ftp sensor volts so you can look at the pressure you apply,

this will also allow you to see the drop in pressure if it exists and how fast it drops, if its only a .020 leak and we find it at the tank,

its not going to drop very fast. First you will need to get your atmospheric reading in volts from the ftp sensor, most are, 2.4-2.8v,

GM uses, 1.4-1.6v, Ford uses, 2.4-2.7v, Toyota uses, 3.0-3.8, look at these with the gas cap removed, lower numbers less than

atmospheric are a vacuum, higher numbers are a pressure, now that we have that number, we can add pressure above that number.

So first, to eliminate the rest of the system, we will remove the vent hose from the tank that goes to the canister, and we will adapt our

one way valve and/or maybe just the pressure pump to this hose, then start pumping pressure into the tank while watching the ftp sensor volts,

or if your just watching the gauge on the pump, if it will hold, and watch the pressure begin to increase once you get a fair amount

built up beyond your base reading, by adding a volt or two to the atmospheric reading, you could go higher, but not beyond

4.5v, now see if will hold the pressure. Don't forget that your one way valve is supposed to be holding your pressure, make sure its oriented

to push thru, then hold, pinch off the hose just to be sure, if it holds now, check the valve, and maybe wire tie the hoses at the nipples.

So if you definitely see a drop here, there are a lot of places it can be, the first place to go would be the fuel cap, either replace with a

known good one or find some way to cap off the filler neck, I usually keep a few of the popular ones in stock. If that corrects your drop in pressure,

probably you have corrected your leak, fuel caps are the most common problem with leaks that small. So if all checks out good with the tank,

you can proceed further with your testing, if not and further inspection is necessary, you will need to drop the fuel tank for visual inspection,

there are plenty of other possibilities, the seal at the pump module, the seal at the ftp sensor, the hose at the filler neck, the tank itself, anywhere

something enters the tank. Once its down you can still pressurize it and use your gas detector to check for vapor leaking, or you could use soapy solution

in a spray bottle and look for bubbles, you will need to remove the filler neck from the vehicle and attach to the tank, or find a way to cap off the tank.

So if all is good, you need to proceed with further testing, probably pressure test the canister by itself, with soapy solution, make sure it's not cracked,

check around the base of the nipples too, you could use your gauge on one side while pumping pressure using the one way valve on the other and see if it holds

pressure.If the canister is good put it back in, but don't connect the tank vent hose, leave it off and plug the nipple on the canister, we already tested the tank good,

remember? Go to the purge line now where it hooks up to the purge valve and put pressure on the system there, if you use the service port, make sure you remove

the valve, now, remove the hose at the vent valve from the canister, and plug that hose we will check that next, doing it in sections helps narrow it down, now we are

looking at everything forward of the vent valve, including the canister itself that already checked good, and the purge valve and put pressure on it and use soapy

solution all over it and make sure its not cracked, check that next, sooner or later it will show up somewhere. The purge valve and vent valve just test them with both

vacuum and pressure with both in the closed position, if they hold vacuum and pressure, there okay in that respect, you should also check there operation,

just put 12v on them and make sure they either open or close, use your vacuum/pressure pump to check that they close all the way. Most of you probably have

the experience necessary to understand whats going on here, hopefully its of some use to you, next, I will outline using the smoke machine.

The Cats meow of smoke machines, although I sold mine after I retired,

this spent very little time on the shelf. Will tear a $2k bill in half, if there was one.

When I would hook mine up, it would be back at the vent valve with it removed, now you will be testing the whole system, but don't go with smoke just yet,

let it pressurize until the flow meter ball drops until it goes as far as its going too and see if it's indicating your .020 leak, if it is, now go ahead and introduce the

smoke and look it over, you probably wont see anything right away, if at all, especially above the fuel tank, .020 is a pretty small leak, but don't be discouraged,

now your going to break it down into small areas and check each one, without smoke, just like in the previous procedure, that's what we will do, but we have no

need to watch the ftp volts since we have the flow meter, so we just test each area while watching the flow meter til it shows the leak in whatever we are testing, it's a

whole lot easier than trying to see some faint wisp of smoke. If an area is good, obviously the ball will drop to zero indicating no flow and shows no leak.

Just do everything individually, you will find the leak in one particular area allowing you to concentrate on that part of the system, at least it has

always worked for me, rather than wasting time trying to see the smoke that's just barely coming out of some where from the front to the back

of the vehicle, once you have it nailed it down to a certain section, it's faster to track it down. You will need some of those spark plug boots and

rubber caps in various sizes to cap off lines or adapt them to the smoke machine in what needs to be done to separate them from the rest of the

system. The worst case is if its somewhere at the tank, although there are areas to check before dropping it for closer inspection, use your gas detector

or your soapy solution on the tank walls if it's a plastic tank especially around the filler neck where it protrudes from the tank, and the hose to the filler

neck itself. Of course you will also need to eliminate the fuel cap, these are usually the big offender of small leaks, check around it with your gas detector,

or go new. I've done literally hundreds of these systems with all types of leaks, small, large, bad fuel caps, cracked tubes, split hoses, damaged

fuel tanks, bad pump installs, I've seen just about everything possible, and the impossible, I even offered a Evap system maintenance package

if the system was beyond 100k, the major components were replaced and the system completely checked and verified. Later on, I will go

over some other "cool" things you can do with the "Smoker"