Ever use your scope to do a compression test? Fluke 98 series II has the test built in as well as others, and it will do it with volts or amps. How do you get this same feature on any scope? Get a good amp probe if you don't have one yet, and use it to do a cranking amps per cylinder test. Its somewhat easy once you understand whats going on during cranking. Fluke 90i-610S was used in these tests, it has two resolutions, 0-100A and 0-600A, and you can use it for a ton of other tests. About $180-200.

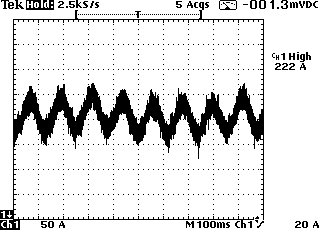

Here is an image of the test on a 88 Ford PU 5.0 V8 with a definite miss at idle, you will have to experiment with the scales to get the waveform to show you the variation from cylinder to cylinder, and it will be different on engines with varying amounts of starter draw, you will need to change resolution on the probe as well. Trigger the scope on #1 cylinder so that you can find the offending cylinder in the waveform. The fuel injection should be disabled by killing the fuel pump during cranking. This may be hard on some applications, worst case would be to kill power at the pump itself. The ignition system has to be working to get the trigger signal off the #1 ignition wire, otherwise the waveform will not be in firing order sync. It may be possible to trigger the scope on the #1 injector on some sequential systems. Even the waveform out of firing order sequence will tell you if cylinder pressure is a factor with the misfire. In the image above, each peak is per cylinder starter draw when each cylinder is on its compression stroke.

After downloading the waveform into the software for my Tekscope, I can view the waveform at any scale I choose. I changed the amps scale to 100A/div, and it looks pretty good. You need to change the scales during the test, to find the best view for each different application. Triggering off number one cylinder, the following cylinders will show up in the firing order telling you which cylinder is down. On this engine, it happens to be #8. Now its easy to go find out whats going on at that cylinder. This cylinder had a burnt exhaust valve found by doing a leakdown test. The high peak on #1 has to be a result of the starter working harder to get cranking speed back up after seeing the weak cylinder.

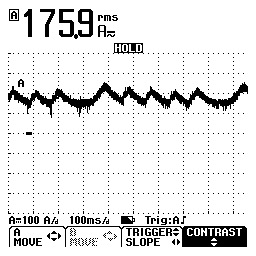

After repairs, the cranking amps per cylinder look much better here. When doing this test, port fuel injection must be disabled without disabling the ignition system, or you wouldn't get a trigger signal off #1 cylinder since there would be no secondary signal on the wire. On some applications this will be tough, since most power relays handle the PCM and the fuel pump. This test doesn't replace power balance test, but if you don't feel like hooking up the big scope, its a quick and dirty way of verifying compression.

Cranking test 88 Ford 5.0 V8 Cylinders #2 and #8

92 Ford 7.5L V8 75k Miles, Cranking amps per cylinder, good.

95 Ford Windstar 3.8 V6 98k miles, Cranking amps per cylinder, untriggered, dead or very weak cylinder.